Control System Components

V

1.3

Control system components

m Operator

Interface

m Controls

Cabinet

m Terminal Rails

m Allen Bradley CLogix chassis

m MK2 controls

chassis

m Interface

modules

m Controlnet

m Overspeed Protection

m Emergency stop

loop

m Motor Control

Centres

Operator interface

l VDU, keyboard

and pushbuttons

l VDU often

touchscreen

l Sometimes

mounted remotely to controls cabinet

l Keyboard slides

or hinges out of controls cabinet if VDU on controls cabinet

l Pushbuttons

soft-wired, time delay applies.

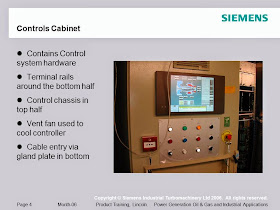

Controls Cabinet

l Contains Control

system hardware

l Terminal rails

around the bottom half

l Control chassis

in top half

l Vent fan used to

cool controller

l Cable entry via

gland plate in bottom

Terminal Rails

l Terminal rails

numbered as per contract drawing

l Generally all

Fire and Gas on one rail

l All DC supplies

on another rail

l Other rails

house interface modules for I/O

Allen Bradley PLC controller

l Control chassis

mounted inside UCP

l Normally 13

slots plus power supply

l PSU on the left

followed by cards

l PLC processor is

Logix 5555 for package and sequence control

l SAM module for

core engine control (fuel and air)

l Other cards are

comms or local I/O

l Most

instrumentation is connected via Controlnet.

MK2 controller

l Up to 4 control

chassis mounted inside TCM

l Up to 15 cards

in each chassis

l I/O cards such

as AIM’s, SIM’s, FIM’s

l PPM for package,

sequence and core engine control

l CEC often run in

separate utility within PPM (BEACON)

l I/O connection

via IFM’s or Controlnet

I/O interface

l Interface

modules, IFM’s, are used to make the field signals compatible with the card

input

l Provide external

relays

l Provide

interface from ribbon cable

l Lots of types

Controlnet

l I/O network made

by Allen Bradley

l Lots of I/O

transmitted over a single network cable

l Dual redundant

l Reduces field

wiring

l Reduces control

system cards

l Can be in

controls cabinet or field mounted

Overspeed protection

l Separate

Overspeed protection

l Mounted in

control cabinet

l Uses MK2 OSM

l Also provides

watchdog for processor

Emergency stop loop

l Emergency stop

pushbuttons around skid

l And at the TCM

l And remotely

(customer)

l Hardwired system

l Inputs from

overspeed and Fire and Gas

l Removes power

from the Fuel block and vent valves

l Latched relay,

reset-able from control interface

Motor Control Centres

l MCC’s

l Low voltage

output from controls activates contactor to put higher voltage onto motor

l Selectable to

Local or Auto

l Overload

protection

l Lamp indication

on front panel

l IDS generally

shows demand not feedback

Generator Control Panel

l GCP, external

supply

l Generator

protection, monitoring and synchronising control

l Modern systems

have a processor based protection relay

Fire and Gas chassis

l HOW fire and Gas

(Tyco)

l Aternative

Detronics or Allestec systems are also used

l Mounted in

control cabinet

l Gas cards

l Zone cards

(UV’s, Heat detectors, MAC’s)

l Extinguishant

cards

l Common

controller

Vibration monitoring

l Vibration

chassis

l BN3500

l Vibration data

sent to controller via MODBUS comms

l Alarm and Trip

data sent by hardwired relay outputs

VGV ram control

l Hydraulic VGV

ram controlled by an ATOS unit

l Converts control

system signal to signal required to drive the ram

l Requires

calibration/setup

l Electric VGV ram

controlled by a Moog driver unit

STAR system

l Small Turbine

Advanced Retrofit

l Throttle valve

control system

l Actuator and

ball valve

l ECU provides

control

l May have

external feedback potentiometer

ECU

lElectronic Control Unit

lUsed to position fuel valves and sometimes VGV ram

lIn retrofit applications on some engine types can be

used to govern the engine

lMounted onskid, offskid or in control cabinet

lCommunication with controller by RS485 or Devicenet

comms

lIf RS485 also some hardwired signals

Integrated Fuel Valve

l Model E Gas Fuel

system packages

l Modular fuel

valve system

l Comprises Block

and vent valves, throttle valves, ECU and instrumentation

l Single I/O

network connection

Batteries and charger

l Lead Acid &

NiCad batteries are used to provide backup power to the TCM

l During normal

operation an Inverter takes supply voltage and feeds a battery charger

l The battery

charger constantly charges the batteries

l The TCM is

normally supplied from the battery charger, in the case of power loss the

batteries provide power to the TCM

Control system components

ANY QUESTIONS ?

Great read thaank you

ReplyDelete