MEASUREMENT

Contents

Measurements -

General.......................................................................

Direct Measurement.......................................................................................

Indirect Measurement.....................................................................................

Instrument Accuracy.......................................................................................

Voltage Transformer Design.......................................................................

Current Transformer Design.......................................................................

Terminal Markings.........................................................................................

Special Dangers with Current Transformers..........................................

Burden.............................................................................................................

Calculation of an instrument transformer

burden.........................................

Location of CTs and VTs..............................................................................

Instruments...................................................................................................

CURRENT AND VOLTAGE TRANSFORMERS FOR

PROTECTION..

CURRENT TRANSFORMERS.......................................................................

Design...........................................................................................................

Operation......................................................................................................

Open-Circuited Current Transformer...........................................................

Short-Time Factor........................................................................................

Accuracy Limit Factor..................................................................................

Specification of Current Transformers..........................................................

Rated Secondary Current.............................................................................

Secondary Winding Impedance....................................................................

Primary Windings.........................................................................................

Application....................................................................................................

Effect of CT Magnetising Current on Relay Setting......................................

Quadrature or Air-Gap Current Transformers............................................

Summation Current Transformer.................................................................

VOLTAGE TRANSFORMERS......................................................................

Accuracy.......................................................................................................

Protection.....................................................................................................

Residual Connection.....................................................................................

Capacitor Voltage Transformers............................................................

Measurements - General

In a.c. power systems it is necessary continually to monitor the

voltage, currents, power and similar quantities in the various parts of the

system. This is done by the use of

instruments - that is by indicating voltmeters, ammeters, wattmeters etc. The same measured quantities are also used to

protect the system by means of relays, which are devices to detect when any of

the quantities is going outside the predetermined limit. They initiate whatever automatic action is

necessary to restore the situation or disconnect faulty or overloaded

apparatus.

Almost all electrical instruments and relays depend for their action

on measurements of voltage or current or combinations of the two. Measurements of frequency are obtained from

analysing a voltage measurement.

Direct Measurement

FIGURE 2.1 - DIRECT MEASUREMENT

Voltage and current samples are taken either

directly or indirectly from the conductors of the circuit to be monitored. In the simplest case (direct measurement) the

voltage is taken by tapping the main conductors. The tappings must always be protected by

fuses which, for a voltage-operated instrument or relay, are quite lightly

rated, though still able to deal with the full fault capacity of the

system. In the 3-phase case a selector

switch may be used to measure voltages between any desired phases, as shown in

Figure 2.1(a).

Direct measurement of current in a

single-phase circuit is obtained by placing the instrument's current-operated

coil in series with a main conductor, shown in Figure 2.1(b). In the 3-phase case it is not possible to

select phases for current measurement unless current transformers are

used. It would otherwise be necessary to

break each phase to connect the ammeter, and this would not be acceptable. Selection with the use of current

transformers is shown under 'Indirect Measurement' in Figure 2.2. Alternatively three separate ammeters may be

used.

The currents in the separate phases can,

however, be measured independently by use of a clip-on type ammeter. Different ammeter instruments can be plugged

into the tongs to give current ranges from 10A to 1000A. On some types the range is altered by a

switch on the tester.

Direct measurement has serious

disadvantages. In high-voltage systems

the instrument or relay would have to be insulated up to the full system

voltage, which for a normal sized switchboard instrument is not practical. Current-operated instruments would not only

have to be insulated up to the full system voltage, they would also have to

carry the full normal current of the circuit and to withstand the extreme fault

currents. This, too, is not practical

except for the lightest circuits.

Indirect Measurement

To overcome these objections indirect

measurement is employed. Transformers

are used not only to scale down the quantities actually measured, but also to

isolate the instrument or relay from the main system voltage. Such transformers, which are designed

specifically for this purpose, are known as instrument transformers.

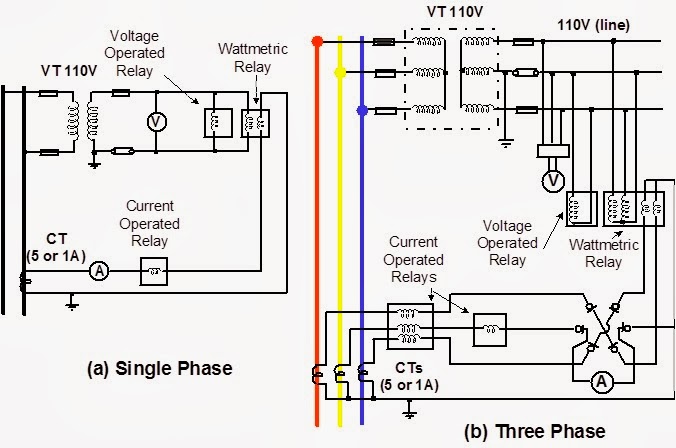

Instrument transformers are of two types -

'voltage transformers' (VT) and 'current transformers' (CT). They are shown diagrammatically in Figure 2.2

for both single-phase and 3-phase systems.

For 3-phase there may be either three separate single-phase VTs (with

their ratios adjusted for the star connection), or else a 3-phase unit, which

is more usual. Current transformers are

always provided as separate single-phase units.

The secondary voltages and currents may be

chosen as desired, but in practice the VT secondary voltage is usually 110V

line-to-line, and the CT secondary current 5A or 1A (refer to a later paragraph

in this section for special precautions when dealing with CT secondaries).

To select the phases between which voltages

are measured, a 3-position selector switch is used, as in Figure 2.1(a), but

connected to the VT secondaries. Further

positions may be provided to measure voltages between each phase and neutral.

To select the phases in which currents are

measured, a special selector switch is used which inserts the ammeter into the

CT secondary of the desired phase and at the same time allows the secondary

currents of the other two phases to pass.

To avoid open-circuiting the CT secondaries, all contacts are of the

make-before-break type. This is shown in

Figure 2.2(b), bottom right.

FIGURE 2.2 - INDIRECT MEASUREMENT WITH

INSTRUMENT TRANSFORMERS

A VT feeds, through secondary fuses (except

in the earthed line), all voltage-operated instruments and relays in parallel,

single- or 3-phase as required.

Current-operated instruments and relays are connected in series with

the CT secondary whose phase is being used.

Fuses must never be used in a CT secondary circuit (see special

precautions). Instrument transformer

secondaries must always be earthed. With

star-connected VT secondaries it is normal practice to earth one phase (usually

the yellow) and not the star-point. CT

secondaries are normally commoned at some point, and it is usual to earth this

common line, as shown in Figure 2.2(b).

Instrument Accuracy

Since the purpose of instruments and relays

is to monitor the actual conditions in the main power line, it is necessary

that VTs and CTs reproduce those conditions, to a stepped-down scale, as

accurately as possible. That is to say

their voltage ratio or current ratio must be correct and constant over their

whole range of operation; they must not introduce undue phase shift while doing

so (important for wattmeters); and they must reproduce unbalance conditions

exactly.

The extent to which these conditions are met

determines the accuracy class of the instrument transformer. A distinction is drawn between 'measuring' and

'protective' types. For measurements,

the accuracy within, and a little above, the normal working range is important,

but accuracy in the overcurrent and fault ranges of current does not matter. On the other hand, a protective CT must

deliver accurate currents in the fault range, whereas accuracy in the working

range is unimportant. This gives rise to

two different design concepts.

The classes of accuracy are laid down by

British Standards. For each type

different ranges of accuracy are specified for measurement and for protective

transformers according to the purpose for which they are to be used. The ranges are as follows:

|

VTs

|

CTs

|

||||

|

Class

|

Voltage Ratio Error

|

Phase Displ

|

Class

|

Current Ratio Error

|

Phase Displ

|

|

Measurement

0.1

0.2

0.5

1

3

|

±0.1%

±0.2%

±0.5%

±1.0%

±3.0%

|

±15' (angle)

±10'

±20'

±40'

not spec.

|

0.1

0.2

0.5

1

3

5

|

±10.25 - 0.1%

±0.5 - 0.2%

±1.0 - 0.5%

±2.0-1.0%

±3%

±5%

|

±10'-5'

±20' - 10'

±60' - 30'

±120' - 60'

not spec.

not spec.

|

|

Protective

3P

6P

|

±3%

±6%

|

±120'

±240'

|

5P

10P

|

±1%

±3%

|

±60'

±60'

|

|

Special

|

|

|

X

|

as specified

|

|

Most indicating instruments on onshore and

offshore switchboards are fed from VTs and CTs of Class 0.5, and most

protective relays from VTs Class 3P and CTs Class 5P. There are, however, exceptions (for example

differential relays are fed from Class X CTs), and it is necessary to refer to

drawings for particular cases.

If it is ever necessary to check or

recalibrate a switchboard instrument or relay, it must always be done with

instrument transformers of a class higher than those with which it normally

runs.

Voltage Transformer Design

A voltage transformer is made basically like an ordinary open-type

power transformer, with separate HV and LV windings. It is, of course, much smaller, having

ratings in the range 15 to 200VA per phase.

The loading on a VT (or CT) is termed 'burden', not 'load'; an

instrument transformer burden is always measured in volt-amperes, never in

watts. At voltages up to those found on

offshore installations most VTs are dry-type, often embedded in synthetic

resin. They are usually located inside

the switchboards. On shore equipments,

especially when associated with high-voltage oil circuit-breakers, VTs are often

in oil-filled tanks.

The high-voltage VT primary fuses are of the HRC type. They have a low current rating but are

capable of breaking the full busbar fault current of the HV system. They are located in the VT compartment and

with some types are embodied in the VT itself.

Access to the high-voltage VT and its fuses is through the VT

compartment door. This cannot be opened

until the VT has been isolated. The

manner of isolation varies with different manufacturers.

Current Transformer Design

A current transformer can take one of two forms. One type is wound like an ordinary

transformer, with primary and secondary windings round a common core. As a CT steps current down, it steps voltage

up. The primary winding, though

connected in the system's high-voltage system, is in fact the LV (high current)

winding as far as the transformer is concerned, and the secondary is the HV

(low current) winding. Wound-primary CTs

are used where the primary current is low and where it is necessary to have

several primary turns to achieve enough ampere-turns in the CT. The examples shown in Figure 2.3(a) and (b)

are typical; burdens are in the range 5 to 30VA per phase. Wound-primary CTs must be able to withstand

the full voltage and fault current of the main system on their primary

windings.

FIGURE 2.3 - TYPICAL CURRENT

TRANSFORMERS

An alternative form of CT is known as the 'bar' or 'ring' type. It has no primary 'winding' as such but uses

the main conductor itself as a 'one-turn' primary. The flux surrounding the conductor, due to

the current it is carrying, links the closed iron core of the CT and induces

voltage in the secondary winding, which is wound as a toroid around the

circular core. The secondary circuit is

closed through its burden, and the current which flows in it is an exact

scaled-down replica of the primary current in the conductor.

Bar-type CTs are generally used whenever the current ratio

(e.g. 1500/1A) is large enough. They are also convenient in that several can

easily be stacked over a single existing conductor. It is very important that they be placed the

right way up, otherwise the secondary terminal voltages and current flow will

be reversed. By convention the secondary

terminal S1 always has the same polarity as primary terminal P1, or as that of

the end of the bar emerging from the face marked P1. This type of CT is shown in Figure

2.3(c). Its construction is not limited

by the fault current of the main system.

FIGURE 2.4 - BAR TYPE CT SHOWING

CONSTRUCTION DETAIL

Another important difference between a CT and other types of

transformer lies in its magnetisation.

The magnetising current, and therefore the flux, of a power transformer

or a VT is constant and depends only on the applied voltage. However a CT when it has no burden is

effectively short-circuited, and no voltage is present, whatever the primary

current; therefore there is no core flux.

If the burden is increased, so also is the voltage for a given current,

as explained below, and this causes the magnetisation to increase. Thus with a current transformer the

magnetisation is variable not only with the current, but it also is increased

depending on the burden connected.

In the limit, if the burden is increased beyond the rating of the

CT, the core will saturate, and the current ratio of the CT will no longer

hold; it will become inaccurate. Moreover

the iron losses will rise sharply and may cause severe overheating of the CT

and possibly damage to it.

Terminal Markings

The terminals of a CT should be marked as indicated in Figure

2.4. The primary current flows from P1

to P2 and it is standard to put P1 nearer to the circuit breaker. The secondary current flows from S1 to S2

through the burden.

FIGURE 2.5 - CT

TERMINAL MARKINGS

Special Dangers with Current Transformers

When a CT secondary circuit is closed, a current flows through it which

is an exact proportion of the primary current, regardless of the resistance of

the burden. In Figure 2.6(a) the

secondary of the CT (assumed to have a ratio of 1000/5A and to have 1000A

flowing in the primary) is carrying exactly 5A, and, since the secondary

terminals S1 and S2 are short- circuited, there is no voltage between them.

FIGURE 2.6 - VOLTAGE AND BURDEN OF A

CURRENT TRANSFORMER

If now the short-circuit be replaced by a resistance of, say, 0.5

ohm (as in Figure 2.6(b)), the same 5A will flow through, causing a volt-drop

of 2.5V and a burden of 5 x 2.5 = 12.5VA.

If the resistance were increased to 5 ohms (as in Figure 2.6(c)), the

terminal voltage with 5A flowing would rise to 25V and the burden to 125VA. The greater the resistance, the greater would

be the voltage and burden until, as it approached infinity (the open-circuit

condition), so also in theory would the voltage (and burden) become

infinite. This cannot of course happen

in practice because the CT would saturate or the terminals flash over due to

the very high secondary voltage between them.

But it does show the danger of open-circuiting the secondary of a

running CT. Lethal voltages can be

produced at the point of opening. This

is why CT secondaries are never fused.

The danger from an open-circuited CT is twofold. It can produce lethal voltages and so is a

very real danger to personnel. The high

voltage across the secondary winding could also cause insulation failure in

that winding, leading at best to inaccuracy and at worst to burnout or fire.

Before ever an instrument or relay is removed from the secondary

loop of a running CT (if such a thing had to be done), the wires feeding that

instrument must first be securely shortcircuited at a suitable terminal box

or, better, at the CT itself. Similarly,

if a running CT is ever to be taken out of circuit, it must first be firmly

shorted. CTs with 1A secondaries are

more dangerous than those with 5A, as the induced voltages are higher.

To prevent this danger many CT secondaries are permanently

short-circuited by a 'metrosil', which is a non-linear element with a high

resistance at low voltages but which breaks down to almost a short-circuit at

the higher and dangerous voltages. It

does, however, somewhat reduce the accuracy of the CT and is not always

acceptable for this reason.

There is also a range of CTs designed to saturate if their burden

becomes excessive, so that even on open-circuit their secondary voltage will

not exceed about 100V. It is not safe,

however, to assume that such CTs are fitted in any particular case.

WARNING

WHENEVER POSSIBLE THE MAIN

CIRCUIT SHOULD BE MADE DEAD BEFORE INTERFERING WITH CT SECONDARIES OR THEIR

INSTRUMENTS OR RELAYS.

Burden

The load of a current transformer is called

the burden and can be expressed either as a VA load or as an impedance. In the former case the VA is taken to be at

the CT nominal secondary current. For

example, a 5VA burden on a 1A transformer would have an impedance of 5 ohms:

|

= 5V

|

impedance = =5 W

or on a 5A

current transformer:

|

= 1V

|

impedance = = 0.2 W

All burdens are connected in series and the

increase in impedance increases the burden on the current transformer. A current transformer is unloaded if the

secondary winding is short-circuited as under this condition the VA burden is

zero because the voltage is zero. The

errors of transformation depend on the angle of the burden as well as its

impedance.

Calculation of an instrument transformer burden

Instrument transformers are rated according

to the burden that they can carry and still remain within their specified

accuracy. The burdens are usually given

in VA units (i.e. power factor is

ignored), and all burdens are simply added together. Manufacturers of instruments and relays

similarly state the burdens of these devices in VA. Thus, if a CT operates an ammeter (2VA), a

current relay (3VA) and, say, the current coil of a kWh meter (4VA), the total

burden on the CT of these three devices will be 9VA.

The burden imposed by long secondary pilot

leads, however, cannot be ignored. If,

for example, the total resistance of a CT secondary run were 0.5 ohms (go and

return) and the CT had a 5A secondary, the total volt-drop across the pilots

would be 0.5 x 5 = 2.5 V. With 5A

current flowing in them, the burden of the pilot leads would be 2.5V x 5A =

12.5VA, and this would need to be added to that of the instruments (9VA above)

to give a total burden on the CT of 12.5 + 9 = 21.5VA. It must therefore have a rating sufficient to

meet this total burden. In general,

pilot leads impose far less VA burden on a 1A current transformer than on a

5A.

In Figure 2.5 a 20VA CT with full-load

secondary current of 5A supplies two ammeters, a current relay, a wattmeter and

a kWh meter with VA burdens as shown. The

pilot leads have a resistance of 0.1 ohm per core. Is the 20VA rating of the CT sufficient?

FIGURE 2.7 - CALCULATION OF CT BURDEN

Total instrument burden = 2 + 2 + 3 + 2 + 4 = 13VA.

Total pilot load resistance = 2 x 0.1 = 0.2W.

With 5A secondary current, volt-drop in leads is 5 x 0.2

= 1 V.

Burden imposed by both leads = 5A x 1 V = 5VA.

\ Total burden on CT = 1 3 + 5 = 1 8VA.

As the CT is rated 20VA, it has sufficient

margin.

The reader should work out for himself what

would be the total burden if the CT had a 1A secondary.

Location of CTs and VTs

Current and voltage transformers can be

located anywhere desired where the primary conductors are available, but in HV

switchgear they are usually incorporated in special chambers in the switchgear

unit itself. Manufacturers' arrangements

vary a great deal and the relevant manuals should be consulted before

attempting to locate any current or voltage transformers

Instruments

A.C.

instruments include voltmeters, ammeters, wattmeters, varmeters, power

factor meters, frequency meters and synchroscopes. Voltmeters, ammeters and frequency meters are

almost all of the moving-iron or transducer-operated type, with an accuracy of

2% full-scale deflection. Wattmeters and

varmeters are of the dynamometer type, and power factor meters and

synchroscopes have two sets of fixed coils and a moving-iron armature. All voltage-operated coils (except those for

415V or 440V or less which may be direct-fed) are fed through VTs, and all

current-operated coils through CTs at all voltages.

Since wattmeter, varmeter, power factor meter

and frequency meter movements tend to be expensive, an alternative which is

often used is the transducer-operated instrument. Here the VT and CT signals are fed into static

electronic ac/dc transducers, and a d.c. voltage signal is produced from each

which faithfully represents the a.c. watts, vars, power factor or

frequency. These are led to simple d.c.

voltmeter-type moving-coil instruments, but which are scaled in watts, vars,

power factor or hertz. Many such

instruments can be connected in parallel.

Figure 2.8 shows typical connections.

FIGURE 2.8 - TRANSDUCER OPERATED

INSTRUMENTS

Where two or more such instruments are used from the same

transducer, they are connected in parallel.

Some instruments have their transducer in the instrument case; others

have the transducer in a separate box, especially if it operates more than one

instrument.

Kilowatt-hour or megawatt-hour meters are also fed through VTs and

CTs whose connections are the same as for a wattmeter.

CURRENT AND VOLTAGE TRANSFORMERS FOR PROTECTION

CURRENT TRANSFORMERS

The current transformer is well established

but it is generally regarded as merely a device which reproduces a primary

current at a reduced level. A current transformer

designed for measuring purposes operates over a range of current up to a

specific rated value, which usually corresponds to the circuit normal rating,

and has specified errors at that value.

On the other hand, a protection current transformer is required to

operate over a range of current many times the circuit rating and is frequently

subjected to conditions greatly exceeding those which it would be subjected to

as a measuring current transformer.

Under such conditions the flux density corresponds to advanced

saturation and the response during this and the initial transient period of

short-circuit current is important.

It will be appreciated, therefore that the

method of specification of current transformers for measurement purposes is not

necessarily satisfactory for those for protection. In addition an intimate knowledge of the

operation current transformers is required in order to predict the performance

of the protection.

Current transformers have two important

qualities:

1.

They

produce the primary current conditions at a much lower level so that the

current can be carried by the small cross-sectional area cables associated with

panel wiring and relays.

2.

They

provide an insulating barrier so that relays which are being used to protect

high voltage equipment need only be insulated for a nominal 600V.

Operation

A representation of a ring-type current

transformer is shown in Figure 2.9. R2 is the

secondary winding resistance, Ie the magnetising

current and Rb, and Xb are the burden

resistance and reactance. The primary

ampere-turns must equal the sum of the secondary ampere-turns and the magnetising

ampere-turns.

N1I1

= N2 (I2 + Ie )

In practice Ie is small

compared to I2 and is therefore ignored in all CT calculations

with the exception of those concerned with ratio and phase angle error.

The magnetising current depends on the

voltage V2 which in turn depends on the product of the

secondary current and the impedance of the burden plus the CT secondary winding

resistance. That is, by Ohm's Law:

V2 =

I2 (R2 + Rb +jXb)

Note. The term (R2 + Rb +jXb) is not a simple

arithmetic sum as Xb is

90° out of phase with R2 and Rb

and so must be added by vectors. To

denote this the prefix "j", is used which literally

means "advance by 90°" The voltage I2Xb

is therefore 90° ahead of I2R2

and I2Rb

and Vb

= I2(Rb +jXb)

FIGURE 2.9 - EQUIVALENT CIRCUIT OF A RING-TYPE

CURRENT TRANSFORMER

If a vector diagram is drawn, Figure 2.9,

then the ratio error, which is the difference in magnitude of I1

and I2,

and 0, the phase angle error, become apparent.

The magnetising current Ie

lags V2

by 90°.

It can be seen that if the burden was wholly resistive then the ratio

error would be a minimum and phase-angle error maximum, whereas if the burden

was wholly reactive then the ratio error would be maximum and the phase-angle

error minimum.

FIGURE

2.10 VECTOR DIAGRAM OF A RING-TYPE CURRENT TRANSFORMER

Figure 2.11 shows a magnetising

characteristic for a 100/1A current transformer. It has been previously stated that Ie

is small compared to I2 up to and beyond the

knee-point of the characteristic. Hence

the ratio and phase-angle errors will also be small. This means that the primary-secondary current

relationship will be maintained to this point,

i.e. where the product I2 (R2 + Rb

+jXb) is 120V,

e.g.

if R2 = 1W and Rb

+jXb = 7.5 +j0W then linearity would be maintained up to a secondary current of

|

Alternatively, if linearity is required up

to, say 20 x CT rating then the total impedance should not exceed

|

R2

+ Rb +jXb = =

6W

FIGURE

2.11 - CT MAGNETISING CHARACTERISTIC

Open-Circuited Current Transformer

If the impedance Rb

+jXb is very high then the voltage calculated from

I2 (R2 + Rb +jXb) would be very large, well above knee-point value and Ie would become significantly large in the ampere-turn balance equation

N1I1 = N2 (I2 + Ie) and I2 would be reduced. The limiting value is when the CT secondary winding is open-circuited and I2 = 0. All the input ampere-turns will he used as magnetising ampere-turns and will drive the current transformer Into saturation. As can be seen from Figure 2.11 the greatly increased magnetising current will not cause much increase to the average voltage. However, the change in flux from zero to the knee-point value is not accomplished in ¼ cycle but in perhaps 1/100 of this time. Thus the rate of change of flux and, therefore, the induced voltage during this period would be about 100 times the knee-point voltage. Insulation can be damaged by this high short-duration voltage and overheating caused by the great increase of iron losses.

I2 (R2 + Rb +jXb) would be very large, well above knee-point value and Ie would become significantly large in the ampere-turn balance equation

N1I1 = N2 (I2 + Ie) and I2 would be reduced. The limiting value is when the CT secondary winding is open-circuited and I2 = 0. All the input ampere-turns will he used as magnetising ampere-turns and will drive the current transformer Into saturation. As can be seen from Figure 2.11 the greatly increased magnetising current will not cause much increase to the average voltage. However, the change in flux from zero to the knee-point value is not accomplished in ¼ cycle but in perhaps 1/100 of this time. Thus the rate of change of flux and, therefore, the induced voltage during this period would be about 100 times the knee-point voltage. Insulation can be damaged by this high short-duration voltage and overheating caused by the great increase of iron losses.

Short-Time Factor

When a current transformer is used in a power

system it may be subjected to fault current many times larger than its primary

rating and, therefore, it must he able to withstand the effects of this current

for the time for which it is likely to persist.

The maximum current which it can carry without mechanical and thermal

damage is expressed as a multiple of its rated current and is known as the

short-time factor. For example, a

current transformer of ratio 200/5 which is capable of withstanding a current

of, say, 13,000 A would have a short-time factor of 65. Such a short-time factor would always be

associated with a period of duration of the current for example 3 s. Smaller currents would be permissible for

longer periods, the permissible time increasing as the square of the reduction

of current. Larger currents, however,

are not necessarily permissible for any period of time, since electromagnetic

forces have also to be considered.

Accuracy Limit Factor

When a current transformer is used to

energise a protective relay it must maintain its characteristic ratio up to

some multiple of its rated current. This

multiple, which depends on the type and characteristics of the protection, may

be 10, 20 or some even higher value and is known as the "Accuracy Limit

Factor".

The small ratio error introduced by the

magnetising current is often compensated for in the case of measuring current

transformers by Slightly modifying the ratio of primary to secondary turns from

the nominal ratio. For example, a 100/1

current transformer might have one primary turn and 98 secondary turns so that the transformation

ratio would appear to he 100 to 1.02 A, but when it is used to supply its rated

burden the secondary current is reduced from the above value to 1 ampere by the

magnetising losses.

Although the burden of a protective scheme is

only a few VA at rated current, if the accuracy limit factor is high the output

required from the current transformer may be considerable. On the other hand, it may be subjected to a

very high burden. For example, in the

case of overcurrent and earth-fault protection having elements of similar VA

consumption at setting, if the overcurrent elements are set at 100% an

earth-fault element set at 10% would have 100 times the impedance of the

overcurrent elements. Although

saturation of the relay elements modify this somewhat, it will be seen that the

earth-fault element is a severe burden and the current transformer is liable to

have considerable ratio error in this case.

For this reason it is not very much use applying turns correction to

current transformers used for protective purposes and it is generally simpler

and more satisfactory to wind them with turns corresponding to the nominal

ratio.

Specification of Current Transformers

A method of specifying current transformers

for protective purposes is detailed in BS3938.

In this specification they are defined in terms of rated burden,

accuracy class and accuracy limit.

Standard values of rated burden are:

2.5, 7.5, 10, 15

and 30 VA.

Two accuracy classes are quoted 5P and 10P

which gives a composite error at rated accuracy limit of 5% and 10%

respectively.

Standard accuracy limit factors are:

5, 10, 15, 20 and

30.

The method of describing a current

transformer is as follows: 15VA Class 5P20

which means that it is rated for a burden 5VA and will not have more

than 5% error at 20 times rated current.

It is frequently more convenient to refer

directly to the maximum useful voltage which can be obtained. In this connection, the knee-point of the

magnetisation curve is defined as that point at which an increase of 10% of

secondary voltage would increase the magnetising current by 50%. Design requirements for current transformers

for general protective purposes are frequently specified in terms of knee-point

voltage magnetising current at the knee-point or at some other point, and

secondary resistance. These are known in

general as 'Class X', current transformers.

Rated Secondary Current

Current transformers are usually designed to

have rated secondary currents of 0.5A, 1A or 5A. Most burdens will require a definite amount

of VA at rated current and consequently will have an impedance which varies

inversely as the square of the rated current, so that the value of the rated

secondary current does not appear to be important. Many burdens, however, are situated at some

distance from the corresponding current transformers and, as the wire size of

the interconnecting leads is usually large enough to carry the current produced

by a current transformer of any secondary rating, the leads introduce a

definite resistance and therefore more burden at the higher rated currents,

e.g. lead resistance 1 ohm at 1A

correspond to 1VA; lead resistance 1W at 5 A

corresponds to 25VA. Clearly in all

cases where leads may be appreciable there is a great advantage in using the

lower rated current transformer. Modern

practice favours the use of the 1A secondary windings.

Secondary Winding Impedance

Bearing in mind the high value of secondary

current which a protective current transformer may be required to deliver, it

is desirable to make the secondary winding resistance as low as practicable to

limit copper tosses and therefore heating.

In the case of wound primary-type current

transformers winding reactance also occurs, although its precise measurement

and definition is a matter of some difficulty.

Ring-type current transformers with a single symmetrical primary

conductor and a uniformly distributed secondary winding have no secondary reactance.

Primary Windings

To achieve a reasonable output from a current

transformer having a primary rating of 80A or less would require a large core

area and therefore it is more economical to increase the primary winding from a

single turn to two, three or more turns.

This of course necessitates an increase in secondary turns which

increases knee-point voltage for a given core area. The additional primary turns may be attained by

passing the primary conductor through a ring-type transformer a number of times

or it may be a specially constructed transformer with a primary winding.

Application

In specifying current transformers the

connected burden and mode of operation must be taken into account paying

attention not only to the wide range of devices which may be connected, but

also to the variation of impedance over the range of setting any relay. For example, the normal burden of an

overcurrent relay is 3VA at setting. The

normal setting range of the relay is 50% to 200% of nominal current. Therefore a 1A relay set to 50% would have a

setting current of 0.5 A and the voltage across the coil at this current would

be

|

V = = 6V

and the impedance would be

|

Z = = 12W

At a setting of 200% the setting current

would be 2 A, the voltage

|

V = = 1.5V

and the impedance would be

|

Z = = 0.75W

If the characteristic of the relay is to be

maintained up to 20 times the relay setting, then a knee-point voltage not less

than

20 x 6V = 120 V for a 50% setting

or 20

x 1.5V = 30 V for a 200% setting

would be required. The former is more onerous and therefore the

lowest setting must be taken into account when specifying the knee-point

voltage. There is, however, an alleviating

factor in that a relay operating at 20 times its setting will have saturated

magnetically and therefore the impedance will be reduced. The reduction for an overcurrent relay is

about half the impedance at setting which means that in the above case a

knee-point voltage of 60 V would be satisfactory

In many cases the current transformers

associated with the over-current protection must also cater for earth-fault

relays. An earth- fault relay having a

minimum setting of 20% would have voltage at setting of

|

= 15V

and the impedance would be

|

= 75W

The maximum earth-fault level may be

restricted to, say, twice the CT primary rating and therefore 10 times the

relay setting. The knee-point voltage

should therefore be greater than 10 x 15V = 150V, or allowing for saturation,

75V.

In this case the size is determined by the

earth-fault relay. A suitable current

transformer would be a 7.5VA Class 5P10.

This would produce a voltage of 7.5V at rated current when connected to

a 7.5W burden and would have only 5% error at

10 times rated current, i.e. at a

voltage of 10 x 7.5V = 75 V.

From the specification in the form 7.5 VA

Class 5P10, the knee-point voltage can be estimated. If it has a 5A secondary winding then at

rated current it would produce 1.5V across the rated burden and at 15 times rated

current 22.5V. As a rough guide the

knee-point voltage is the product of the VA rating and the accuracy limit

factor divided by the rated secondary current.

Class 5P is specified when phase-fault

stability and accurate time grading is required. When these are unimportant Class 10P is

suitable.

It may be that more than one relay is to be

connected to one set of current transformers in which case the total burden

must be calculated. It is generally

sufficient to add the burdens arithmetically but it should be borne in mind

some alleviation may be available by adding the burden vectorially in case of

difficulties in design.

It is not good engineering practice to

specify a current transformer which is substantially larger than necessary as

there is no advantage in performance and its cost would be higher and its

dimensions greater.

Effect of CT Magnetising Current on Relay Setting

The overall setting of a protection system is

affected by the magnetising current of the current transformers and, whilst the

effect may not be significant in the case of overcurrent relays, it can have

some effect on the overall setting of an earth-fault relay and can sometimes

have a profound effect on differential protection systems particularly where a

large number of current transformers are connected together. For example, a busbar zone protection scheme.

The primary operating current (P.O.C.) of a

protection System is the sum of the relay setting current and the magnetising

current of all the connected current transformers at the voltage across the

relay at setting multiplied by the CT ratio.

Quadrature or Air-Gap Current Transformers

A quadrature or air-gap transformer is merely

a current transformer with an air gap so that most of the primary ampere-turns

are used to magnetise the core. This means

that the flux, and therefore the secondary voltage, is proportional to primary

current. More correctly, the secondary

voltage is proportional to the rate of change of flux and therefore lags the

primary current by 90° hence the name quadrature current

transformer.

Summation Current Transformer

There are two applications of the summation

current transformer. One is the adding

together the secondary current from a number of current transformers and is

mainly used for measuring purposes. The

other is used in pilot-wire protection systems to convert the inputs from the

current transformers in each phase to a single output for comparison with a

similar output from the remote end via the pilot wires.

In the former case any input winding not in

use must be left open-circuited.

VOLTAGE TRANSFORMERS

The voltage transformer in use with

protection has to fulfil only one requirement, which is that the secondary

voltage must be an accurate representation of the primary voltage in both

magnitude and phase.

To meet this requirement, they are designed

to operate at fairly low flux densities so that the magnetising current, and

therefore the ratio and phase angle errors, is small. This means that the core area for a given output

is larger than that of a power transformer, which increases the overall size of

the unit. In addition, the normal three-

limbed construction of the power transformer is unsuitable as there would be

magnetic interference between phases. To

avoid this interference a five-limbed construction is used, which also

increases the size. The nominal

secondary voltage is sometimes 110V but more usually 63.5V per phase to produce

a line voltage of 110V.

Accuracy

Only in a few of the many protection

applications is the phase angle and ratio errors likely to be much

significance. However the likelihood of

a voltage transformer being provided solely for protection is small and

therefore the more stringent accuracies of instrumentation and metering are

usually required.

All voltage transformers are required by

British Standard to have ratio and phase-angle errors within prescribed limits

over a 80% to 120% range voltage and a range of burden from 25% to 100%.

For protection purposes accuracy of

measurement may be important during fault conditions when the voltage is

greatly suppressed. Therefore a voltage

transformer for protection must meet the extended range of requirements over a

range of 5% to 80% rated voltage and, for certain applications, between 120% and

190% rated voltage.

Protection

Voltage transformers are generally protected

by HRC fuses on the primary side and fuses or a miniature circuit-breaker on

the secondary side. As they are designed

to operate at a low flux density their impedance is low and therefore a

secondary side short-circuit will produce a fault current of many times rated

current.

Residual Connection

It is important that a voltage of the correct

magnitude and phase angle is presented to directional earth-fault relays and

the earth-fault elements of impedance relays.

As an earth-fault can be any one of the three phases it is not possible

to derive a voltage in the conventional manner.

The solution is to use the residual or broken delta connection as shown

in Figure 2.12

Figure

2.10 - BROKEN DELTA CONNECTION OF A VOLTAGE TRANSFORMER

Under three-phase balanced conditions the

three voltages sum to zero. If one

voltage is absent or reduced because of an earth-fault on that phase, then the

difference between the normal voltage and that voltage is delivered to the

relay. A secondary winding for this type

of connection is in addition to the normal secondary winding.

Capacitor Voltage Transformers

At voltages of 132kV or more, the cost of

electromagnetic voltage transformers is very high. A more economical proposition is the capacitor

voltage transformer. This is virtually a

capacitance voltage divider with a tuning inductance and an auxiliary

transformer as shown in Figure 2.11.

Any simple voltage-divider system suffers

from the disadvantages that the output voltage varies considerably with

burden. If, however, C2 is tuned with a

reactor, the burden can be varied over a wide range with very low

regulation. It is not feasible to

produce directly the usual 63.5 V as C2 would be impossibly large and therefore

a potential of around 12 kV is developed across C2. This is applied to the electromagnetic unit

and the 63.5 V derived from its secondary winding. This method also has the advantage that a

tapped winding can be provided to accommodate the fairly wide tolerances of

capacitors.

Figure

2.11 - CAPACITOR VOLTAGE TRANSFORMER

No comments:

Post a Comment