TRANSFORMERS - GENERAL

VA Rating

Every transformer has a maximum output current that it can deliver at its standard output voltage. This VA rating (KVA or MVA for large power transformers) is dependent on the ambient temperature or cooling provided. Exceeding the VA rating will cause over-heating of the core and windings and subsequent damage.

Cooling

Cooling requirements for the VA rating(s) are usually listed on the

nameplate along with the ambient operating temperature. Oil filled

transformers, will include the type of cooling at which the full rated

load can be delivered. A typical 1000kVA oil filled transformer that

has radiators to allow natural air cooling of the oil, would be listed as:

Transformer Rating: 1000 KVA 550C ONAN, which stands for the

capability to supply 1000KVA with a temperature rise of 550C with

normal oil circulation (no fans or pumps).

The various abbreviations that you will find for transformer cooling

are:

• ONAN cooling. ONAN is an abbreviation for Oil Natural

(thermo-syphon) circulation with Air Naturally circulated for

cooling.

• ONAF abbreviation denotes that the transformer has provision

for Oil Natural Air Forced cooling. Forced air-cooling would

allow the rating to be increased by a small amount.

• OFAF stands for forced (pumped) oil circulation and forced

(fan) air-cooled radiators.

• OFW - The main transformers at large generating stations are

OFW types with oil forced cooling, where the oil is, in turn,

cooled by water.

For large power transformers, there are usually multiple ratings

depending on the type of cooling applied. Typical cooling

requirements for transformers equipped with circulating oil pumps and

air-cooled radiators are usually listed as:

450/600/750 MVA 650C

ONAN/ONAF/OFAF

This rating, with a 650C ambient temperature rise, would be:

• 450 MVA with normal oil circulation, no fans or oil pumps on.

• 600 MVA with normal oil circulation, fans on.

• 750 MVA with both fans and oil pumps on.

Frequency

All transformers are designed for the optimum flux linkages and

lowest heating and power loss at a certain frequency. An induced

voltage is created by an alternating magnetic field. At higher-thanrated

frequency, there is excessive core loss due to lower efficiency in

flux linkages. At lower-than-rated frequency, there is excessive

winding loss due to decrease of flux linkages.

Transformers are basically inductors:

• Increasing frequency increases impedance and lowers current

(less flux).

• Decreasing frequency decreases impedance and increases

winding current (more heat).

Voltage

The available winding insulation is the governing factor for the voltage rating on the transformer. As well as the rated operating voltage, the rated transient (spike) voltage that the transformer can withstand is usually included. This is listed as the impulse level or BIL.

Phase

Single Phase on a Common Iron Core

Quite often, large three-phase power transformers are installed by

constructing three single-phase transformers and tying their input or output windings together. Such as the case for most main power output transformers that transform the generator power from high current, isolated phase buses to high voltage electrical system. Construction of a single three-phase transformer would be out of the question.

Single Phase on a Common Iron Core

Most power transformers encountered are of this construction for size and cost efficiency.

Windings

Separate windings (standard).

Fig 1 Two Winding Transformer

Auto-transformer.

The autotransformer has the same ratios (turns, voltage and current) as a transformer with two separate windings. However, the output is tapped off a portion of the single winding. This configuration yields itself to creating variable tapped output voltages, as we will discuss later.

Connections

The common transformer connections are single phase, 3 phase star, 3 phase delta, or zigzag. (The latter connection is used explicitly in grounding transformers and will not be discussed in this course.)

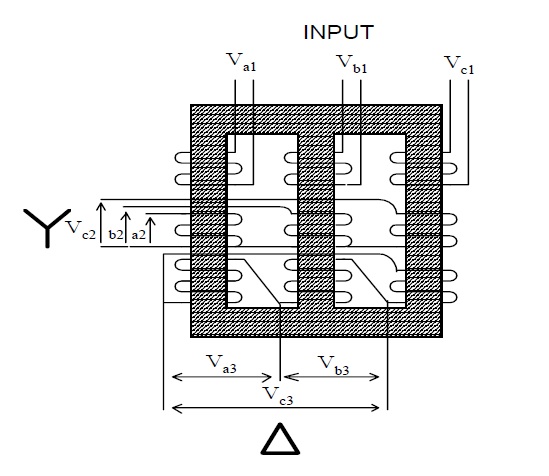

Figure 3 below is an example of the connections for a three-phase

transformer. Individual three-phase inputs are transformed into two

separate outputs - one star or “wye”, the other delta.

The primary and secondary windings on most three-phase

transformers are connected in either star or delta formation.

The star point, (see Figure 3) of a star winding is connected to ground NotesN otes:

and this ensures the line terminals have equal and balanced voltages to ground. The delta winding, because it does not have a common (star) point, is not connected to ground at the transformer.

Taps

Winding taps are provided in transformers to adjust the turns ratio

between input and output and, hence, adjust the output voltage.

• Off-load taps are for use in transformers that rarely require

output voltage adjustments. For example, a generator

main-power output transformer.

• On-load taps that require frequent operations as customer or

system load fluctuates during the day.

Engineering 4all, Practical Engineering, Free Learning Source, By Photos You Can Learn What you are studying.

Pages

- Home

- Industrial Instrumentation

- Manuals Requests:

- DNA Testing

- What is Electrical Engineering?

- How Satellite TV Works?

- Website Hosting?

- What is cord blood?

- What is Data Recovery?

- Online Engineering Education

- General Electric Turbine

- Nature Photos

- Electrical Glossary

- Electrical Engineering Overview

- Electrical Courses and Lectures

- Valves

- Fundamental of Electricity 1

- Fundamentals Of Electricity 2

- Fundamentals Of Electricity 3

- Electrical Distribution Equipments Part A

- Electrical Distribution Equipments Part B

- Electric Motors Course

- ABB

No comments:

Post a Comment