2.1 THE SQUIRREL CAGE INDUCTION MOTOR

2.1.1 The

3-phase Motor

The normal induction motor operates only on a 3-phase

supply. It consists of a stator wound

with a 3-phase winding in slots on the inside of the yoke. The windings are distributed around the

stator so that in a so-called ‘2-pole’ motor their axes are spaced 120° apart.

Each winding end is brought out to a terminal. The other ends are usually star-connected

within the machine. In some instances

the machine may be delta-connected, in which case all six ends may be brought

out to six or three terminals.

If a 3-phase supply is connected to the three stator terminals, such an arrangement gives rise to a rotating magnetic field. This completes one revolution in one cycle of supply; that is to say, with a 60Hz system frequency the field rotates at 60 rev/s, and with a 50Hz supply at 50 rev/s. This is called the ‘synchronous speed’. (See ‘Fundamentals of Electricity 2’, Chapter 3.)

FIGURE

2.1

MAGNETIC FIELD, EMFs AND CURRENTS IN ROTOR

Inside the stator is a rotor which is free to rotate and

has no electrical connections to it - that is to say, no brushgear. The rotor could be of solid iron, but it is

more usually laminated and fitted with uninsulated copper or aluminium bars in

slots round its outer edge, the bars being short-circuited at both ends by

brazed metal rings, as shown in Figure 2.1.

The bars and rings together form a cage-like assembly,

and this form of motor, by far the most numerous, is called ‘squirrel

cage’. There are variations on this

arrangement, but they are not found offshore, and not often onshore.

Figure 2.1 shows only the rotor. The stator and its windings already described

in the earlier manual are not shown, but the rotating field which the stator

produces is indicated in blue. This is

the only manifestation of the stator that the rotor ‘sees’.

While the rotor is at rest and therefore stationary, the

rotating field from the stator passes through all the rotor conductors in turn,

generating emfs in them by Faraday’s Law of Induction. Because all the rotor bars are

short-circuited, these emfs cause currents to flow through the bars and

end-rings as indicated in red in the figure.

The direction of the currents will change as the passing field changes

from N to S and back again.

The rotor bar currents react with the magnetic field

surrounding them to produce a sideways mechanical force on each bar, as

explained in Chapter 6 of the manual ‘Fundamentals of Electricity 1’. By Fleming’s Left-hand Rule these forces act

on all bars in the same direction and produce a combined torque on the rotor in

the direction of the field rotation.

This causes the rotor to accelerate from rest. In more simple terms the rotor can be

considered as being ‘dragged around’ by the rotating field.

As the rotor accelerates, the relative speed of the

field passing it becomes less, the frequency and amount of the emfs and the

rotor currents get less, and the mechanical force on the conductors and the

torque on the rotor, after increasing for a time, also become less. Finally the rotor settles down to a speed

slightly less than that of the field (the synchronous speed), when the emfs are

at very low frequency and are just sufficient to maintain the rotor current and

torque against the load. This settled

speed is typically 1 to 2% below synchronous, and the difference is called the

‘slip’. For example, a 2-pole, 60Hz

motor would have a synchronous speed of 3 600 rev/mm; the motor nameplate may

show the motor’s rated speed as 3 540 rev/mm, which would indicate a slip of

1.67% at full-load. At less than

full-load the slip is reduced and the speed approaches nearer to

synchronous. Conversely, as mechanical

load is applied, the slip increases, and the rotor’s induced emf and hence its

current rises, which gives an increase in driving torque to meet the load.

Thus induction motors have nearly, but not quite, a

fixed speed just below synchronous, and it cannot be controlled (as in a d.c.

motor) except by complicated and expensive equipment which is not installed in

offshore or onshore installations. For

this reason it is often called an ‘asynchronous motor’.

As the rotor gathers speed, it generates increasing

back-emf in the stator, causing the stator current to fall. At full speed, as load is applied, the slip

and the rotor currents increase, causing increasing stator currents (and

therefore motor ‘load’) by transformer action.

When the creation of rotating fields was discussed in

the earlier manual it was explained that, with one stator winding per phase,

the field made one revolution per cycle.

If, however, there were two parallel windings per phase, making a total

of six windings disposed at 60° (instead of 120°) intervals, the field would make only half a revolution per

cycle. A machine so wound is called a

‘4-pole’ motor; at 60Hz its field rotation would be only at 1 800 rev/mm, and

this therefore would be its synchronous speed.

As already explained, the full-load speed is just below

synchronous, differing from it by the small slip, so that the nameplate rated

speed of 4-pole motors at 60Hz will be around 1 750 rev/mm. These in fact are far more numerous than the

faster 2-pole motors. Similarly

6-pole motors (synchronous speed at 60Hz 1 200 rev/mm) will have rated speeds of about 1 160 rev/mm. With 50Hz supply systems the rated speeds for 2-, 4- and 6-pole motors will be about 2 950, 1 475 and 980 rev/mm respectively.

6-pole motors (synchronous speed at 60Hz 1 200 rev/mm) will have rated speeds of about 1 160 rev/mm. With 50Hz supply systems the rated speeds for 2-, 4- and 6-pole motors will be about 2 950, 1 475 and 980 rev/mm respectively.

It should be particularly noted that the induction motor

is not strictly a constant-speed motor, as its speed varies over a small range

of up to about 2% between no-load and full-load. Neither is it a variable-speed motor in the

sense that it can be used for variable-speed drives, as can be done with d.c.

motors. For most practical purposes however,

such as for driving pumps, compressors and similar plant, it can be regarded as

a constant-speed machine. Only where exact

constant speed is needed would it be necessary to go to a synchronous motor.

2.1.2 The

Single Phase Motor

The 3-phase motor described above depends on the

creation of a rotating magnetic field from static windings in a 3-phase

stator. However, it is possible to

create a rotating field from a single-phase supply provided that it is split

into two parts whose space-displacement and time-displacement are equal - in

this case 90° instead of the 3-phase 120°. Such a motor is called a ‘split-phase’

motor. The principle is described in the

manual ‘Fundamentals of Electricity 2’, Chapter 3.

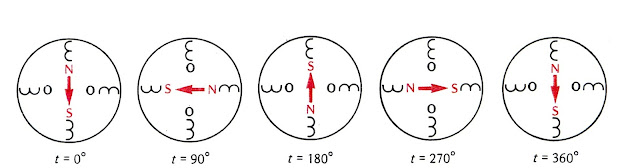

Figure 2.2 shows how the split is achieved. It has four pole windings spaced at equal 90° intervals round the stator.

Opposite pairs of poles have opposite polarities, so that, when one is

producing an N field, the other is producing an 5, and vice versa.

The other pair of windings, 90° displaced, are fed through a capacitor of sufficient size to cause

the current through the second pair of windings to lead by nearly 90° in time on that in the other pair.

Single-phase

Supply

FIGURE 2.2

SPLIT PHASE, SINGLE PHASE (CAPACITOR) INDUCTION MOTOR

FIGURE 2.3

SPLIT

PHASE MOTOR STATOR FIELD

Figure 2.3 shows the polarities at 90° (quarter-cycle) time intervals.

At time t = 360° (on the extreme right) the 12 o’clock

pole is N maximum and the 6 o’clock S maximum.

Both the 3 o’clock and 9 o’clock poles are zero because their currents,

leading 90° on those of the other two, are passing through zero at that

instant.

One-quarter of a cycle (90°) earlier, moving from right to left, at t = 270°, the 9 o’clock pole, whose current leads 90° on that of the 12 o‘clock, was at maximum N, and the 3 o’clock at

maximum S. The poles at 12 and 6 o’clock were zero because their currents were

passing through zero at that instant.

Similarly one-quarter of a cycle still earlier (t

= 180°) 6 o’clock was N and 12 o’clock was S, with 3 and 9 o’clock both

zero. And at t = 90°, 3 o’clock was N and 9 o’clock S, with

12 and 6 o’clock both zero. And so back

to t = 0°, which is the same as t = 360°.

It can be seen from Figure 2.3, moving now from left to

right - that is, from t = 0° to t =

360° - that the N-pole progresses steadily from 12 o’clock at t =

0°, through 3 o’clock, 6 o’clock and 9 o’clock back to 12

o’clock. The S-pole progresses in the

same direction but 180° behind.

Therefore a clockwise rotating field, completing one

revolution in one cycle of time, has been produced from a single-phase

supply. It should be added that the

above explanation has been idealised.

The current in the 3 and 9 o’clock poles will not lead the full 90° on that in the other poles because of resistance and inductance,

but the split is quite sufficient to produce an adequate rotating field. This arrangement is not so efficient as a

proper 3-phase motor, but it meets the requirements for smaller motors.

Once the rotating field has been obtained in this manner

from a single-phase supply, the squirrel-cage rotor will run up to speed and

follow it, with the usual slip, exactly as for a 3-phase motor.

When a split-phase single-phase motor has been run up to

speed, it will continue to run and to deliver power even if the capacitor

winding is disconnected. Therefore all

but the smallest of such motors have their 3 o’clock and 9 o’clock windings,

and the capacitor itself, short-rated.

Once the motor has run up, a centrifugal switch opens the capacitor

circuit. When the motor stops it

reconnects it. In such a motor the 3 and

9 o’clock windings are referred to as the ‘starting winding’ and the other as

the ‘running winding’. On very small

motors the centrifugal switch may be omitted and both windings left in circuit.

The split-phase motor is widely used for domestic

equipment, where only single-phase supplies are usually available. Like the 3-phase equivalent, it is

direct-on-line started and exhibits similar slip, torque and current characteristics. It is sometimes called a ‘capacitor motor’;

the capacitor is usually mounted on the outside of the motor case.

Other methods are sometimes used to achieve the phase

difference between the starting and running windings, but the capacitor method

is by far the most common.

2.2 THE WOUND MOTOR INDUCTION MOTOR

The induction motors so far described use a rotor of the

squirrel-cage type, in which the conductors are uninsulated and where the

rotor-bar currents, induced by the field passing at slip speed, are limited

only by the resistance of the bars themselves and of the end rings and by the

reactance of the rotor. There is no

external control of these currents. It will

be shown later that, when a motor is started by switching it direct onto line,

the initial starting currents are very high, and there is no means of

controlling them at the motor.

FIGURE 2.4

WOUND ROTOR INDUCTION MOTOR

Although these high starting currents are normally

allowed for in the design of the system, it is sometimes necessary to reduce

them. One way of achieving this is by

using a wound rotor. Such a machine has,

instead of a squirrel-cage rotor, one that is wound like a normal machine with

insulated conductors in slots. Three

separate phase windings are provided on the rotor, and they are brought out to

three sliprings, as shown in Figure 2.4.

Under normal running conditions the three sliprings are

short-circuited by an external switch or contactor, but during starting they

are connected to a set of variable resistances.

They introduce into the rotor circuit extra resistance which limits the

rotor current and hence the current drawn by the stator. These ‘starting resistances’ are progressively

reduced as the motor gathers speed (much like the old d.c. starters) until at

full speed they are shorted out altogether, and the machine behaves as a

squirrel-cage motor with short-circuited rotor bars.

It should be noted that the resistances are purely for

starting and are therefore only short-rated.

They are not for speed control, since speed is virtually constant and is

determined by the system frequency.

Inserting the rotor resistances has only a slight effect on the slip and

so very little effect on the speed.

Starting resistances for wound-rotor machines may be of

any variable-adjustment type, or they may be fixed with tappings selected in

turn by contactors where starting control is automatic. In some cases a liquid resistor is used where

three plates are gradually lowered into a tank containing an electrolyte; this

gives a continuously variable control.

Wound-rotor motors and their control gear are far more

expensive than the simple squirrel-cage motor.

None are installed in any offshore and few, if any, in onshore

installations.

+INDUCTION+MOTOR.jpg)

No comments:

Post a Comment